materials

and process

materials

we choose our materials based on the ability to endure urban environments and create resilient places.

WOOD

-

Janka test hardness rating of 1,704 lbs

Life expectancy against rot and insects for 25 years depending on the environmental conditions, and also has excellent durability and weather resistance.

CLASS A fire rating in the US

100% Lacey Act and SVLK compliant; sourced only from countries that are leaders in ecological sustainable forestry

Sourced from Indonesia, Malaysia, and Philippines

-

Acetylation is a process of subjecting a softwood to a vinegar, which turns it into a hardwood by preventing the cells in the wood from being able to absorb water. This creates a wood that is incredibly resilient to the common material stressors of the outdoors.

Acetylated pine comes in silvered or uncoloured. The uncoloured can be be stained to any desired wood tone with an oil based stain.

One of the most resilient woods currently available with a 50 year above ground warranty. Class 1 durability rating.

Insect Resistant

Janka test hardness rating of 922 lbs

CLASS C fire rating in the US

This wood begins its life in sustainably managed forests in New Zealand. These forests are all FSC approved.

-

Janka test hardness rating of 3,597 lbs (one of the hardest wood species known)

Life expectancy against rot and insects for 25 years depending on the environmental conditions, and also has an excellent durability and weather resistance

CLASS A fire rating in the US

Sourced from Brazil, and tropical Central America

-

The process of thermal modification is one where the wood is “cooked” using only steam and fluctuating heat intensities. This alters the natural acids and sugars so they can no longer serve as food source for mold, rot, or fungal decay. It also drastically reduces the moisture content rendering the wood “hydrophobic” creating even more resistance and longevity.

Janka test hardness rating of 1,400 lbs

Life expectancy of 25+ years against rot

Class 1 durability rating

Negative Carbon Footprint

CLASS B fire rating in the US

Sourced from Eastern USA and Canada

-

The process of thermal modification is one where the wood is “cooked” using only steam and fluctuating heat intensities. This alters the natural acids and sugars so they can no longer serve as food source for mold, rot, or fungal decay. It also drastically reduces the moisture content rendering the wood “hydrophobic” creating even more resistance and longevity.

This particular wood is salvaged from local waste streams rather than harvested. Trees are constantly removed due to disease, natural disaster, development, etc. Using these trees for lumber diverts them from the landfill.

Janka test hardness rating of 1,200 lbs

Life expectancy of 25+ years against rot

Class 1 durability rating

Negative Carbon Footprint

CLASS B fire rating in the US

Sourced from across the USA

Metals

-

This alloy has good workability, very good corrosion resistance, high fatigue strength, weldability, and moderate strength all at a light weight.

Exceptional corrosion resistance against seawater and salt spray

Aluminium is a preferred material for powder coating due to its excellent ability to attract and adhere to the powder

Aluminium is also one of the only materials in the world that can be recycled infinitely thus making it highly sustainable

-

Hot-dip galvanizing is the process of coating fabricated steel by immersing it in a bath of molten zinc.

The the steel and the zinc bond extremely well. This bond creates a barrier between the steel and the environment where the galvanized coating sacrifices itself to protect the underlying base steel from corrosion.

Extremely abrasion-resistant, as the inter-metallic zinc layers are harder than the base steel. However, even if the coating is damaged, zincs sacrificial action will protect exposed steel up to ¼ inch away.

process

Detailed manufacturing processes Allow us to constantly advance in our pursuit of excellence. Always Striving for the lowest environmental impact with products designed for urban resilience.

-

Our aluminum is cut on a 8kw fiber laser cutter that is capable of delivering exceptional speed, cut quality and accuracy. BLM LS7 laser cutter .

The precision of laser cutting translates into minimal material waste. The focused beam minimizes the heat-affected zone, optimizing the use of sheet metal and contributing to cost-effectiveness and sustainability.

The non-contact nature of the process eliminates the need for expensive dies, punches, or molds, making it a cost-effective solution for various projects.

Cutting with a Laser delivers clean and smooth edges without the need for additional finishing processes. This not only saves time but also ensures a polished, professional look for the final product.

-

Powder coating is a polyester-based coating that uses accurately sized polyester microbeads that have an electrostatic charge that enables them to adhere to base materials.

Aluminum already has superior corrosion resistance but the additional surface treatment of powder coating provides wear resistance, UV resistance, ease of cleaning and almost infinite colour options.

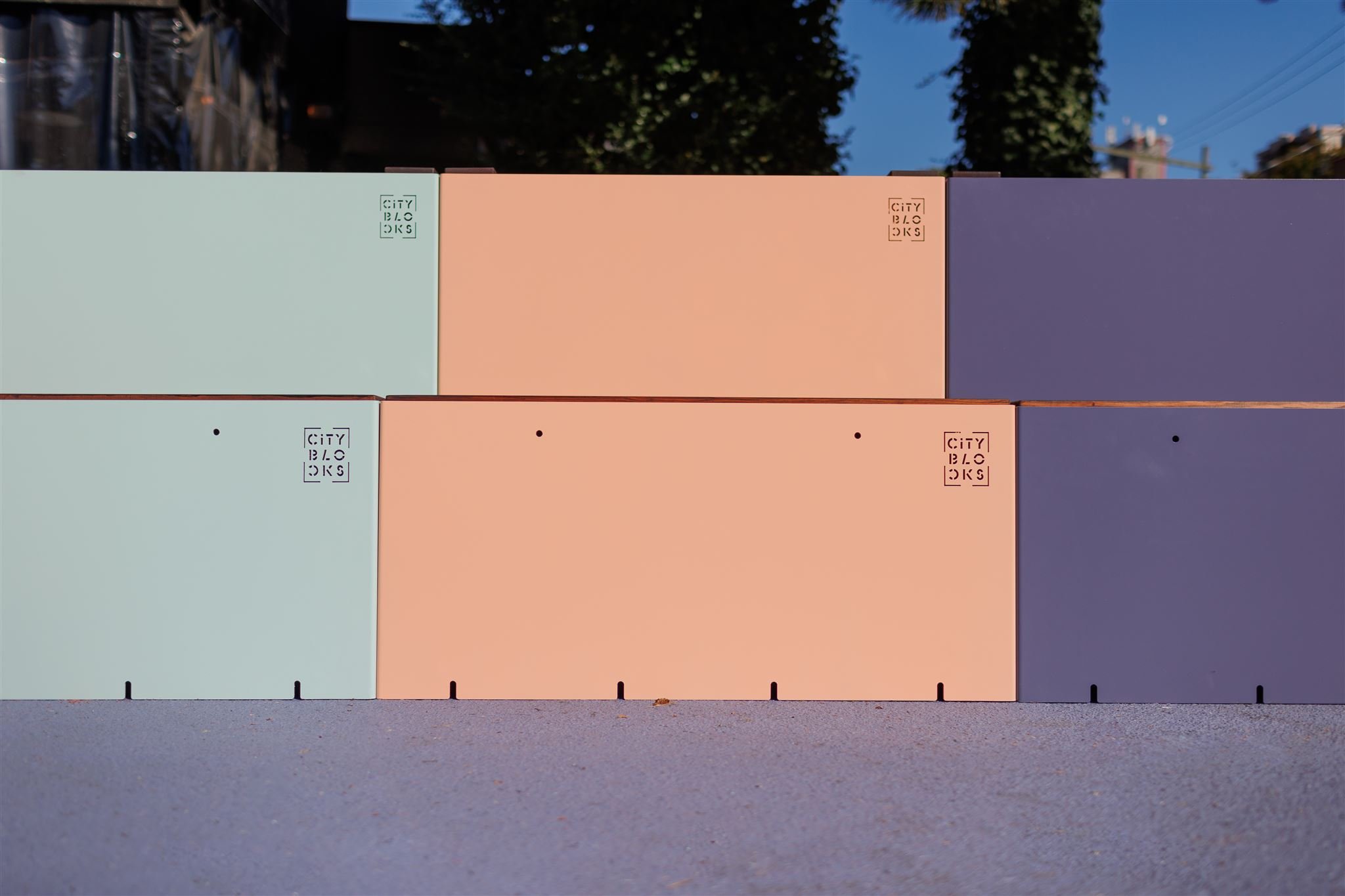

City Blocks offers a full range of colours with the RAL Classic K7 palette . Over 200 colours available to choose from as well as custom colour options.

Due to the nature of the process, powder coating functions with a high level of repeatability. It produces extremely consistent results so you know what you are going to get.

-

Depending on project specifications assembly can be done onsite or at our warehouse/fabrication facility and shipped out as a single piece.

Our products are designed to be “flat packed”. This reduces shipping costs as well as allows us to package more units in a single shipment (reducing carbon footprint).

All hardware used for assembly sourced from an industrial supplier or custom designed and fabricated in house.